Tidal Turbine Rotor Research

An Innovate UK collaboration between Designcraft Ltd and Cranfield University to investigate the performance of tidal turbines optimised for manufacture.

The aim of the project was to investigate the performance variation between optimised and simplified blade geometries. Simplified blade geometries were designed specifically for automated manufacture. These were combined with different rotor configurations, e.g. 5 blade rotors versus 3 blade rotors.

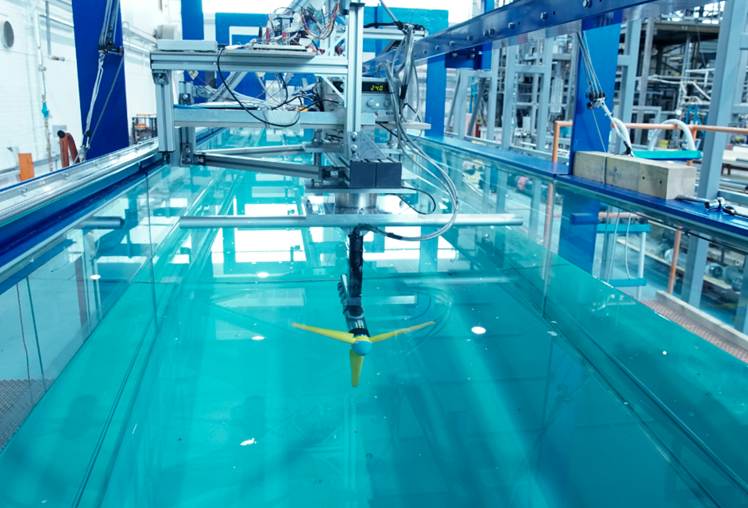

Sixteen 600mm and 1000mm rotors were tested at 3 test tanks (Cranfield, Haslar and Iframar) and were subject to yaw, turbulence and variable flow speeds.

It was possible with these tests to identify “easy to manufacture” blade designs that showed good performance in comparison to more idealised and optimised geometries. This would enable the cost of rotor manufacture to be reduced significantly.

Go Back